Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

PRODUCT CATEGORIES

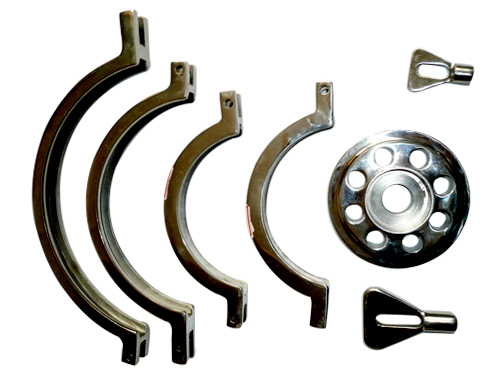

Carbon Steel Pricision Casting

View:

Brand: JUNLONG

Packaging: fumigation-free wooden case

Min. Order: 0.5-100 Kilogram

Place of Origin: Weifang,Shandong Province, China

Transportation: Ocean,Land,Air

Junlong Precision Casting, Inc. plays a major role in the production of Food Machinery Precision Casting used in the food & dairy industry. We serve the Precision Casting of Food Machinery in many areas, from meat slicers, to candy and chocolate producing equipment, ice-cube machines, coffee makers, poultry...

Brand: Junlong

Packaging: wooden case

Supply Ability: 500000

Min. Order: 5 Ton

Certificate: ISO9001:2015

Precision casting of food machinery usually adopts stainless steel material, which requires high surface finish. The stainless steel model is mostly used in 316l, 304 steel, with complex shape. The stainless steel material is mainly completed by silica sol process . Our company has a perfect silicon sol process line...

Brand: JUNLONG

Packaging: fumigation-free wooden case

Min. Order: 0.5-100 Kilogram

Place of Origin: Weifang,Shandong Province, China

Transportation: Ocean,Land,Air

Investment cast for food machinery or food machinery investment castings, is a silica sol process. It is a casting process with little or no cutting. Steel casting for food machinery is excellent process technology in the foundry industry. Its application is very extensive. Food machinery investment cast not only...

Brand: JUNLONG

Packaging: fumigation-free wooden case

Min. Order: 0.5-100 Kilogram

Place of Origin: Weifang,Shandong Province, China

Transportation: Ocean,Land,Air

investment casting of food machinery usually adopts stainless steel material, which requires high surface finish. The stainless steel model is mostly used in 316l, 304 steel, with complex shape. The stainless steel material is mainly completed by silica sol process . Our company has a perfect silicon sol process line...

Brand: JUNLONG

Packaging: fumigation-free wooden case

Min. Order: 0.5-100 Kilogram

Place of Origin: Weifang,Shandong Province, China

Transportation: Ocean,Land,Air

The application of Precision Casts for Food Machinery is very extensive. Food Machinery Precision Casts not only apply to the casting of various types and alloys, but also produce the dimensional accuracy of castings. The surface quality of Castings for Food Machinery is higher than that of other casting methods. Food...

Brand: JUNLONG

Packaging: fumigation-free wooden case

Min. Order: 0.5-100 Kilogram

Place of Origin: Weifang,Shandong Province, China

Transportation: Ocean,Land,Air

Precision casting of food machinery usually adopts stainless steel material, which requires high surface finish. The stainless steel model is mostly used in 316l, 304 steel, with complex shape. The stainless steel material is mainly completed by silica sol process . Our company has a perfect silicon sol process line...

Brand: JUNLONG

Packaging: fumigation-free wooden case

Min. Order: 0.5-100 Kilogram

Place of Origin: Weifang,Shandong Province, China

Transportation: Ocean,Land,Air

Precision casting of food machinery usually adopts stainless steel material, which requires high surface finish. The stainless steel model is mostly used in 316l, 304 steel, with complex shape. The stainless steel material is mainly completed by silica sol process . Our company has a perfect silicon sol process line...

Brand: JUNLONG

Packaging: fumigation-free wooden case

Min. Order: 0.5-100 Kilogram

Place of Origin: Weifang City, Shandong Province, China

Transportation: Ocean,Land,Air

Precision casting of food machinery usually adopts stainless steel material, which requires high surface finish. The stainless steel model is mostly used in 316l, 304 steel, with complex shape. The stainless steel material is mainly completed by silica sol process . Our company has a perfect silicon sol process line...

China Precision Casting Of Food Machinery Suppliers

Food Machinery Precision Casting or food machinery investment casting, silica sol process. It is a casting process with little or no cutting.

Cast food machinery is an excellent process technology in the foundry industry. Its application is very extensive. Food machinery cast not only applies to the casting of various types and alloys, but also produces the dimensional accuracy of castings. The surface quality is higher than that of other casting methods, and even castings that are difficult to cast and which are difficult to cast have high temperature resistance and are not easily processed can be cast using investment casting.

In wax pattern process,we mix stearic acid and paraffin wax in wax pattern making,as you know,it is better than polyethylene,and the wax deformation is small.

In shell making,we adopt automatic sand-covering production line, which was invented under the guidance of our general manager.The indoor temperature was controlled by air-conditions,keeping the temperature at 24℃±1℃, which can make the castings much more stable,the internal tissues much more well-proportioned.

In shell hardening process,we use aluminium chloride to harden the shell.This can make the shell so hard that it can`t be distorted,at the same time the bug which the casting may have will be decreased.If there are letters or numbers in it,they will be much clearer.

In dewaxing process,about 95% of the castings suppliers adopt the original water dewaxing technics,but we using the advanced steam dewaxing technics,which we are very proud of. This can effectively avoid the air-hole and sand-hole, making the casting look much nicer.

In smelt process, we use middle frequency furnace, avoiding the emergence of the oxide; in molten steel control part, we use Germany-imported direct reading spectrometer machine, assuring its quality before the molten steel out of the furnace. During this process we use ERP production and management software to get the feedback information.

In shell-knock out process, we have special machines,which can decrease the hitting and knocking, easily made by manual shell knocking out.

In shot-blasting process, we have crawler-type and hanging shot-blasting machine, with steel shot 0.5-0.8, making the products smooth.Of course, if the customer wants it look much nicer, we also can carry out sand-blast treatment.

In heat treatment process, we use electric furnace, and adopt double-temperature control in order to heat the products equally. As a result, the products will have great metallurgical structure.

Our tolerance can reach at the grade of 5-7 according to our country`s tolerance standard.

In machining process,we have 12 CNC machining centers and some other machines, so we can make further machining if the customers need.

Hot Products

New Products

Home > Products > Stainless Steel Precision Casting > Precision Casting Of Food Machinery

Send Inquiry

Ms. Anna

Tel:86-0536-7669966

Fax:86-0536-7669966

Mobile Phone:+8618363688899

Email:info@Junlongcast.com

Address:No 2084,eight road.Fangzi district , Weifang, Shandong

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.