Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

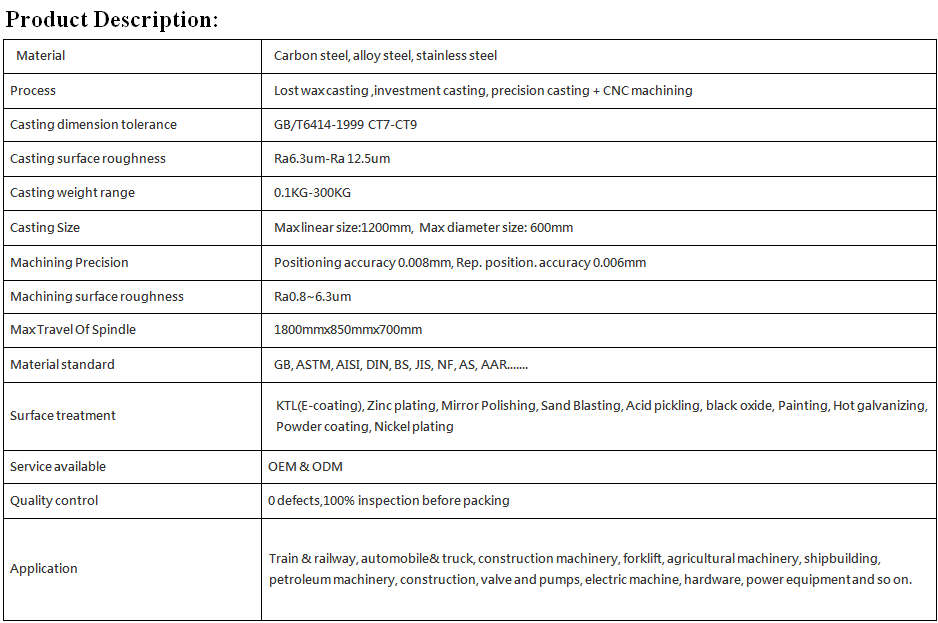

Brand: JUNLONG

Casting Method: Thermal Gravity Casting

Process: Lost Wax Casting

Molding Technics: Gravity Casting

Application: Machinery Parts

Material: Alloy Steel

Surface Preparation: Polishing

Surface Roughness: Ra6.3

Machining Tolerance: +/-0.01mm

Standard: AISI

Certification: ISO 9001:2008

Packaging: fumigation-free wooden case

Transportation: Ocean,Land,Air

Place of Origin: Weifang City, Shandong Province, China

Port: Qingdao Port

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF

Junlong foundry is a professional forklift parts manufacturer in China.We carry a wide precison Investment Casting for forklift Parts.As a first class investment casting supplier,we have advanced production process-lost wax casting or lost foam casting and are able to manufacture forklift castings with alloy steel,carbon steel,manganese steel,ect.

1.Reduce costs:secondary machining is one of the expensive process for manufacturing forklift parts.Investment casting will eliminate or reduce machining as it is netshape parts.Advantages of investment casting forklift parts from our foundry:

2.Design flexibility:Unlike other manufacturing ways,investment casting allow various complex shapes of forklift parts,eliminating the consideration of expensive assemblied parts.

3.Close tolerance and good surface finish:investment casting forklift parts will have relatively close tolerance and smooth surface,which will be good for assembling.

In wax pattern process, we mix stearic acid and paraffin wax in wax pattern making,as you know, it is better than polyethylene, and the wax deformation is small.

In shell making, we adopt automatic sand-covering production line, which was invented under the guidance of our general manager. The indoor temperature was controlled by air-conditions, keeping the temperature at 24℃±1℃, which can make the castings much more stable,the internal tissues much more well-proportioned.

In shell hardening process, we use aluminium chloride to harden the shell. This can make the shell so hard that it can`t be distorted, at the same time the bug which the casting may have will be decreased.If there are letters or numbers in it, they will be much clearer.

In dewaxing process, about 95% of the castings suppliers adopt the original water dewaxing technics, but we using the advanced steam dewaxing technics,which we are very proud of. This can effectively avoid the air-hole and sand-hole,making the casting look much nicer.

In smelt process, we use middle frequency furnace, avoiding the emergence of the oxide; in molten steel control part, we use Germany-imported direct reading spectrometer machine, assuring its quality before the molten steel out of the furnace. During this process we use ERP production and management software to get the feedback information.

In shell-knock out process, we have special machines, which can decrease the hitting and knocking, easily made by manual shell knocking out.

In shot-blasting process, we have crawler-type and hanging shot-blasting machine, with steel shot 0.5-0.8,making the products smooth. Of course, if the customer wants it look much nicer, we also can carry out sand-blast treatment.

In heat treatment process, we use electric furnace, and adopt double-temperature control in order to heat the products equally. As a result, the products will have great metallurgical structure.

Our tolerance can reach at the grade of 5-7 according to our country`s tolerance standard.

In machining process, we have 12 CNC machining centers and some other machines, so we can make further machining if the customers need.

Alloy Steel Investment Casting divides into Forklift Parts Investment Casting, Agricultural Machinery Parts Investment Casting, Petroleum Parts Investment Casting, and Chemical Parts Investment Casting.

Product Categories : Carbon Steel Pricision Casting > Forklift Parts Castings

Home > Products > Carbon Steel Pricision Casting > Forklift Parts Castings > Alloy Steel Precision Casting

Send Inquiry

Ms. Anna

Tel:86-0536-7669966

Fax:86-0536-7669966

Mobile Phone:+8618363688899

Email:info@Junlongcast.com

Address:No 2084,eight road.Fangzi district , Weifang, Shandong

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.